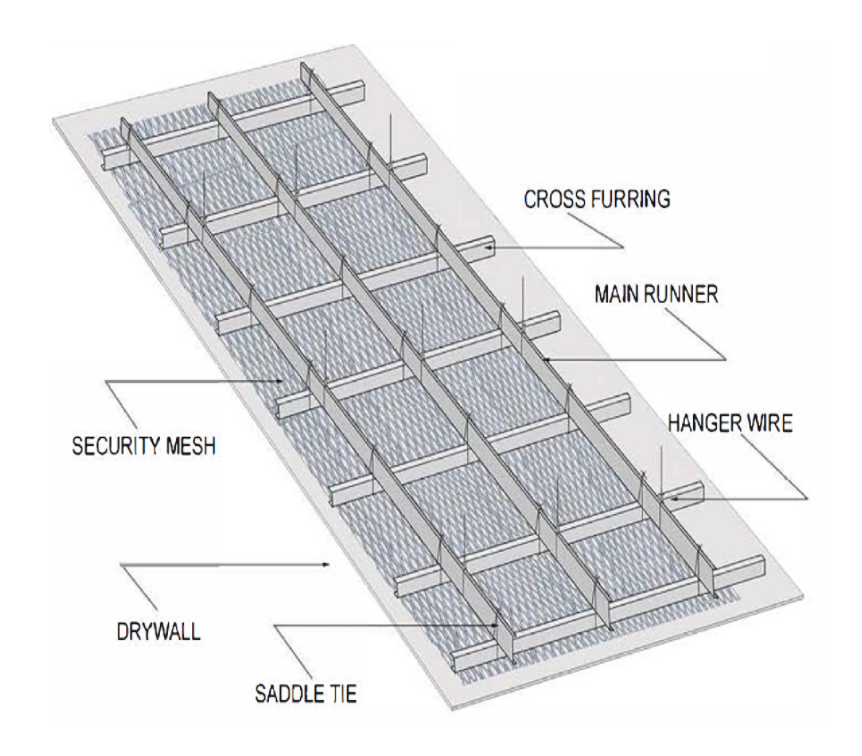

- Security Mesh™ was developed and introduced by AMICO in the late 1980s as a penetration barrier for use behind drywall finishes. The Security Mesh™ in combination with the patented Secura Clip® fasteners create a system that designers and security professionals can count on to provide the highest levels of physical security.

Security Mesh™ & Secura Clip® fasteners – the “Behind the Drywall” penetration barrier

- Security Mesh™ was developed and introduced by AMICO in the late 1980s as a penetration barrier for use behind drywall finishes. The Security Mesh™ in combination with the patented Secura Clip® fasteners create a system that designers and security professionals can count on to provide the highest levels of physical security.

NEW Ballistic Security Mesh™

The Ballistic Penetration Barrier Behind Drywalls

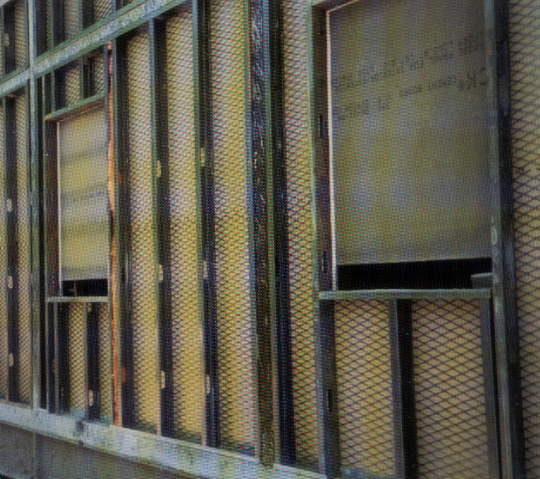

- Since Security Mesh™ was introduced in 1989, Security Mesh™ is now specified in virtually all federal, state, and local Government buildings. Security Mesh™ covers both offices and correction facilities. Security Mesh™ is specified by Homeland Security, the FBI, ATF, Treasury Department and the Department of Defense. Security Mesh is everywhere.

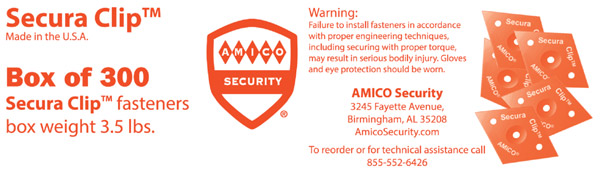

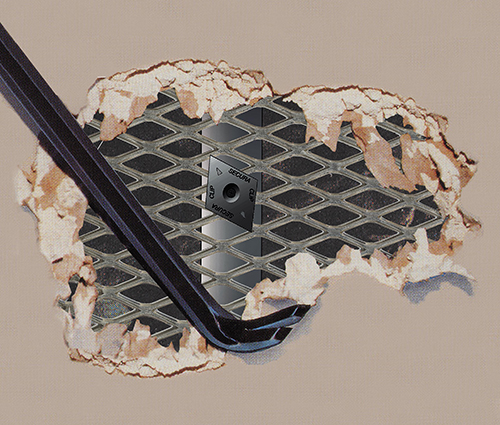

Secura Clip® Fasteners

- AMICO’s patented Secura Clips®complete the system. Secura Clips® are specifically designed to work with Security Mesh™. Secura Clip® fasteners have a recessed center hole allowing the Tek screw to seat at the surface of the mesh and not create humps and bumps alerting intruders to the penetration barrier. Secura Clip® fasteners provide over 68% more holding strength than standard screws alone.

- For best performance AMICO Security Mesh™, Secura Clip® fasteners need to be used. Install clips to metal framing using bugle head self-tapping screws penetrating the framing member a minimum of 3/8-inch. With wood framing use 1-5/8-inch drywall screws allowing the fastener to penetrate framing a minimum of 1-1/2-inches. Standard spacing is 12-inches vertically per framing member for both vertical and horizontal surfaces.

- Gypsum finish is installed directly over Security Mesh™. No need for other materials for added intrusion protection. AMICO has supplied numerous projects requiring mesh to be attached to both sides of the framing members.

Secura Clip® Fasteners

- AMICO’s patented Secura Clips® complete the system. Secura Clips® are specifically designed to work with Security Mesh™. Secura Clip® fasteners have a recessed center hole allowing the Tek screw to seat at the surface of the mesh and not create humps and bumps alerting intruders to the penetration barrier. Secura Clip® fasteners provide over 68% more holding strength than standard screws alone.

- For best performance AMICO Security Mesh™, AMICO Secura Clip® fasteners need to be used. Install clips to metal framing using bugle head self-tapping screws penetrating the framing member a minimum of 3/8-inch. With wood framing use 1-5/8-inch drywall screws allowing the fastener to penetrate framing a minimum of 1-1/2-inches. Standard spacing is 12-inches vertically per framing member for both vertical and horizontal surfaces.

- Gypsum finish is installed directly over Security Mesh™. No need for other materials for added intrusion protection. AMICO has supplied numerous projects requiring mesh to be attached to both sides of the framing members.

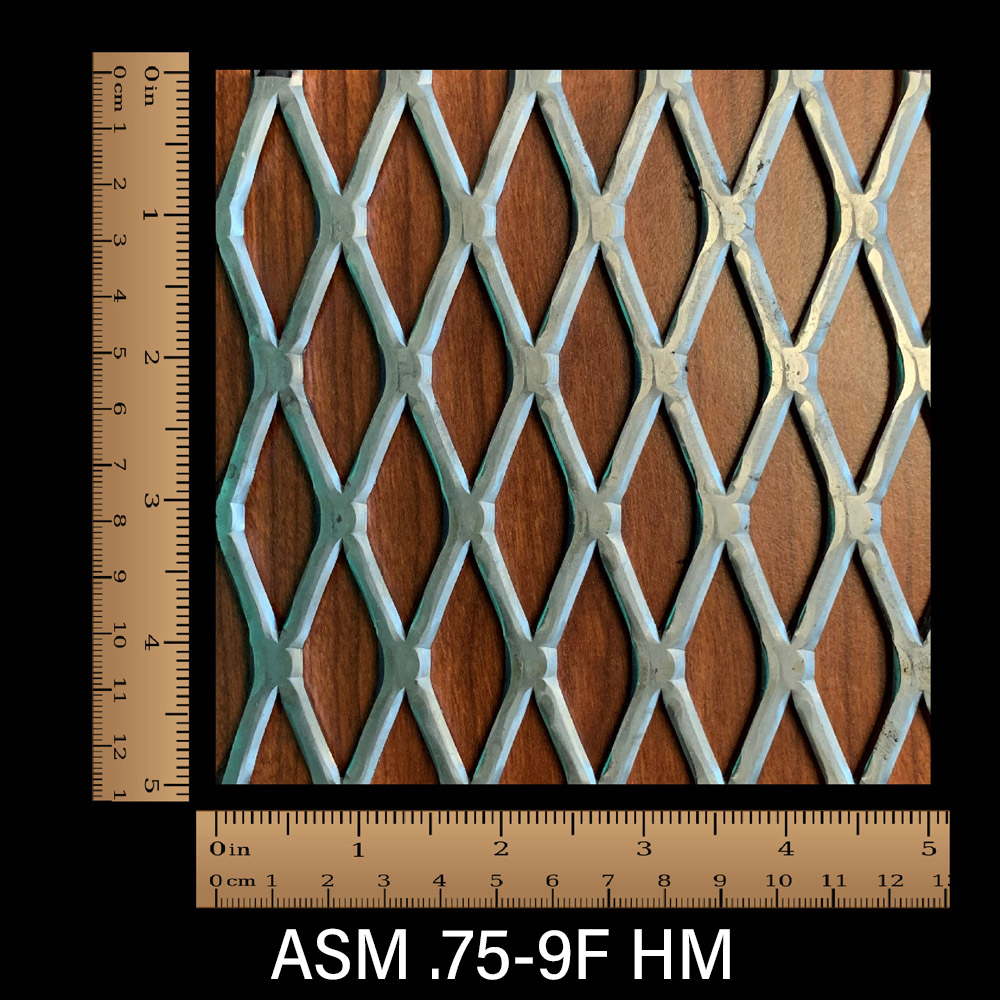

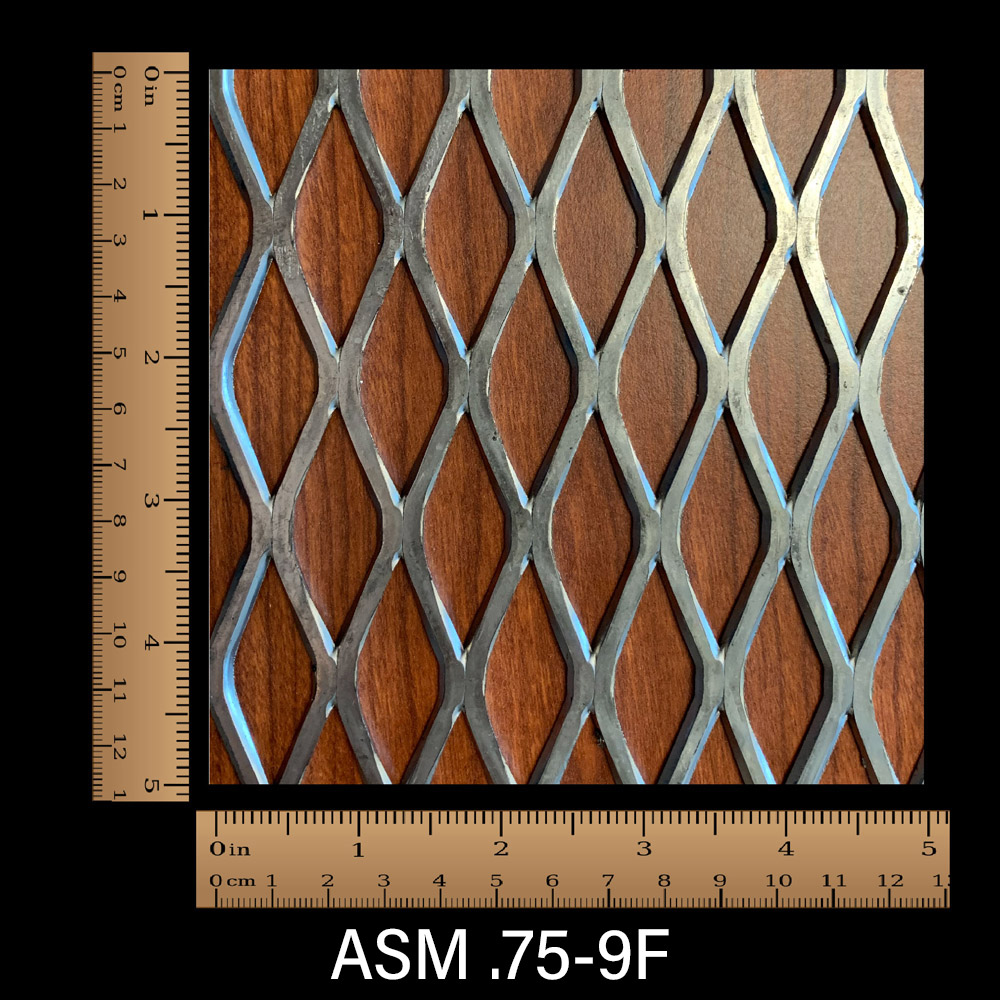

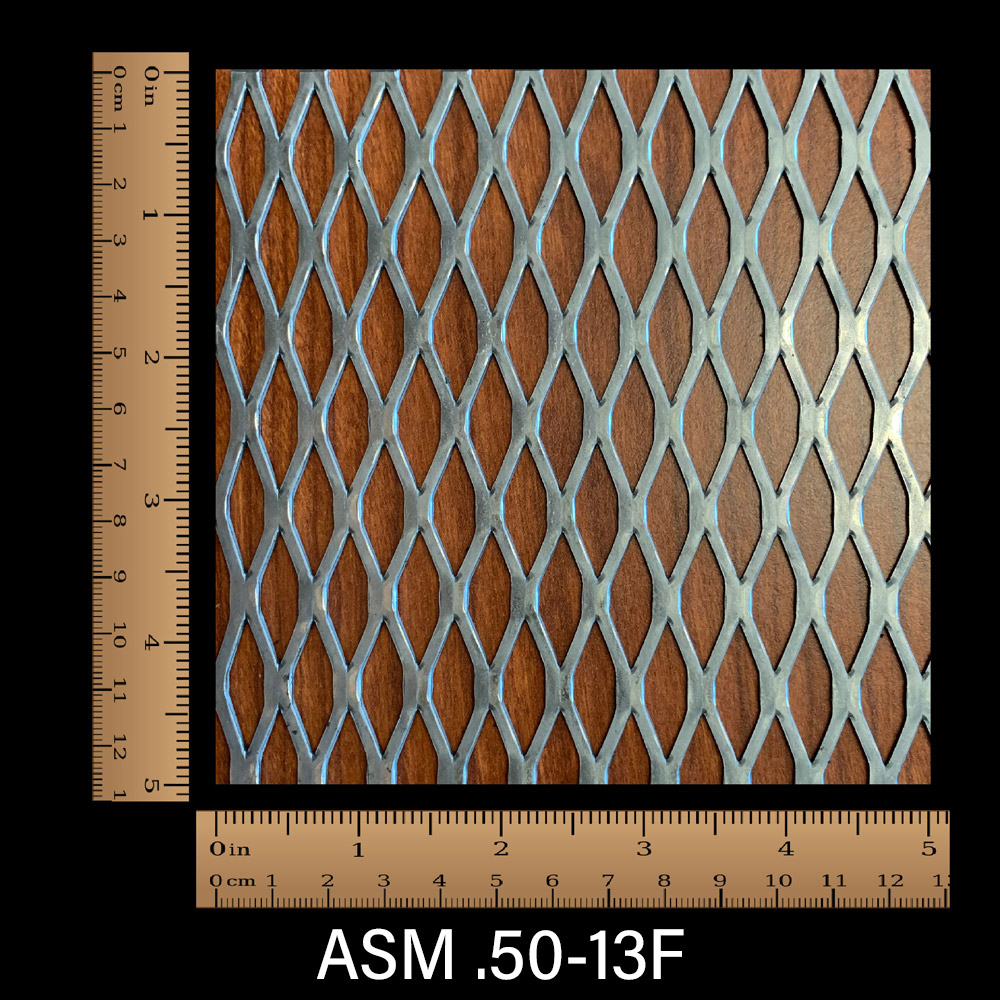

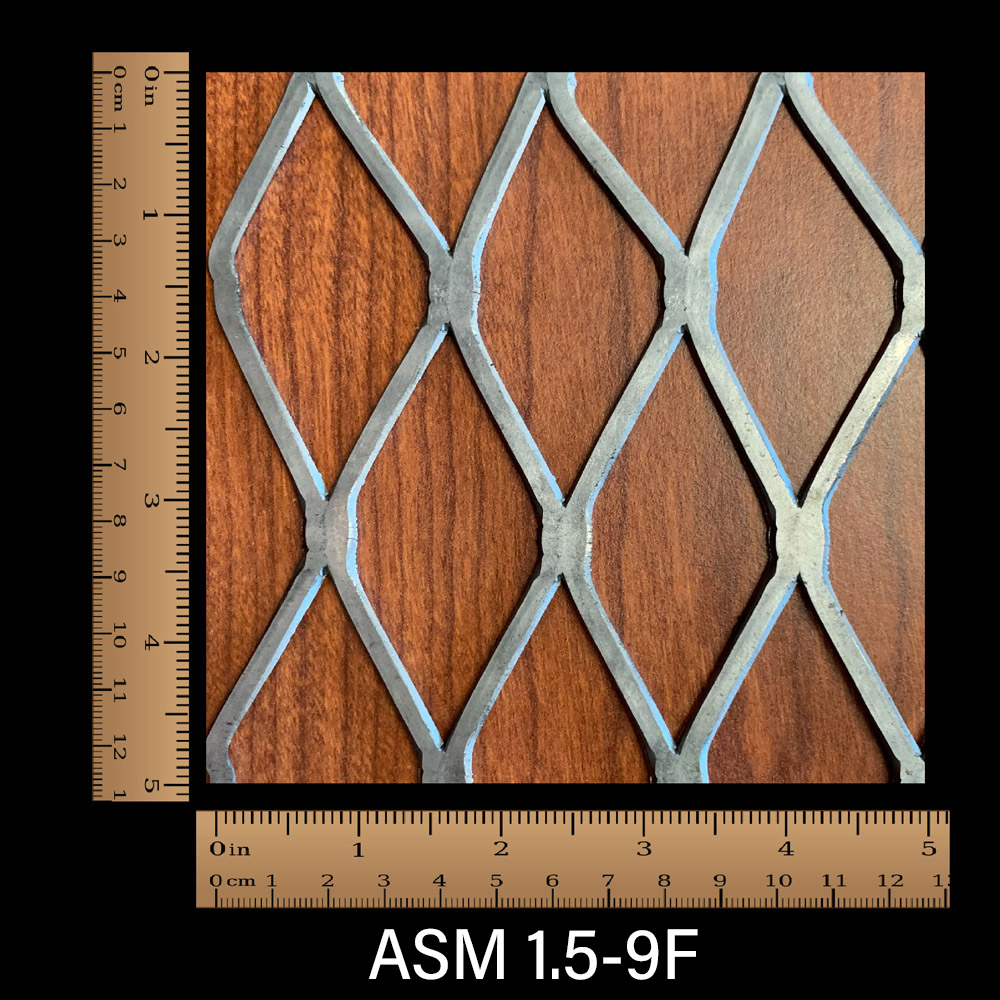

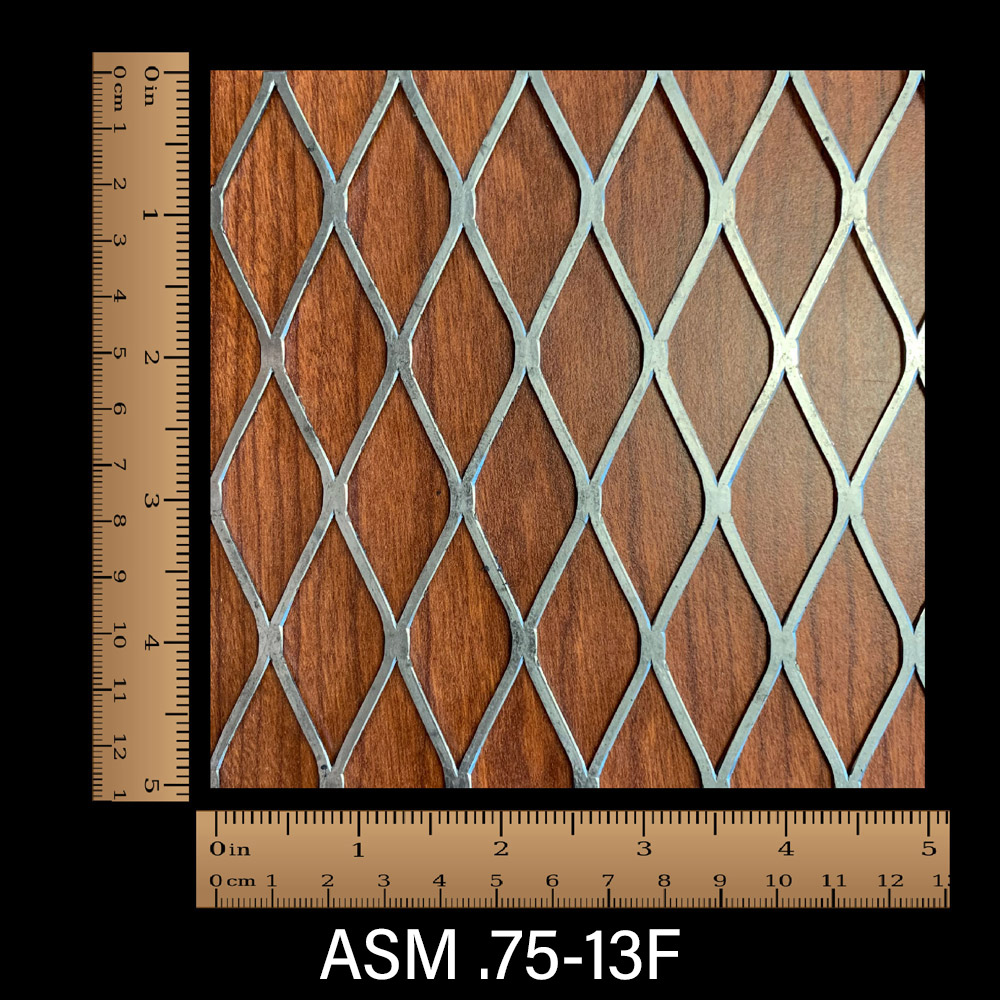

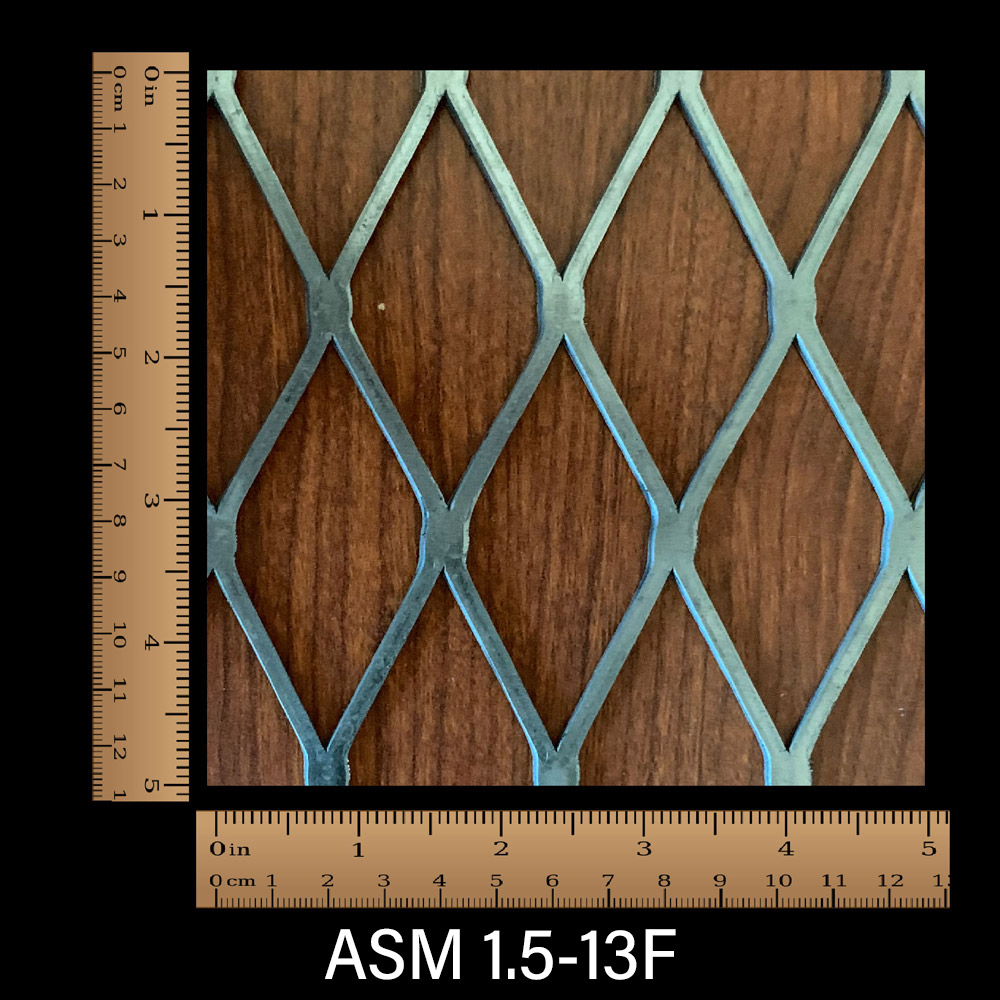

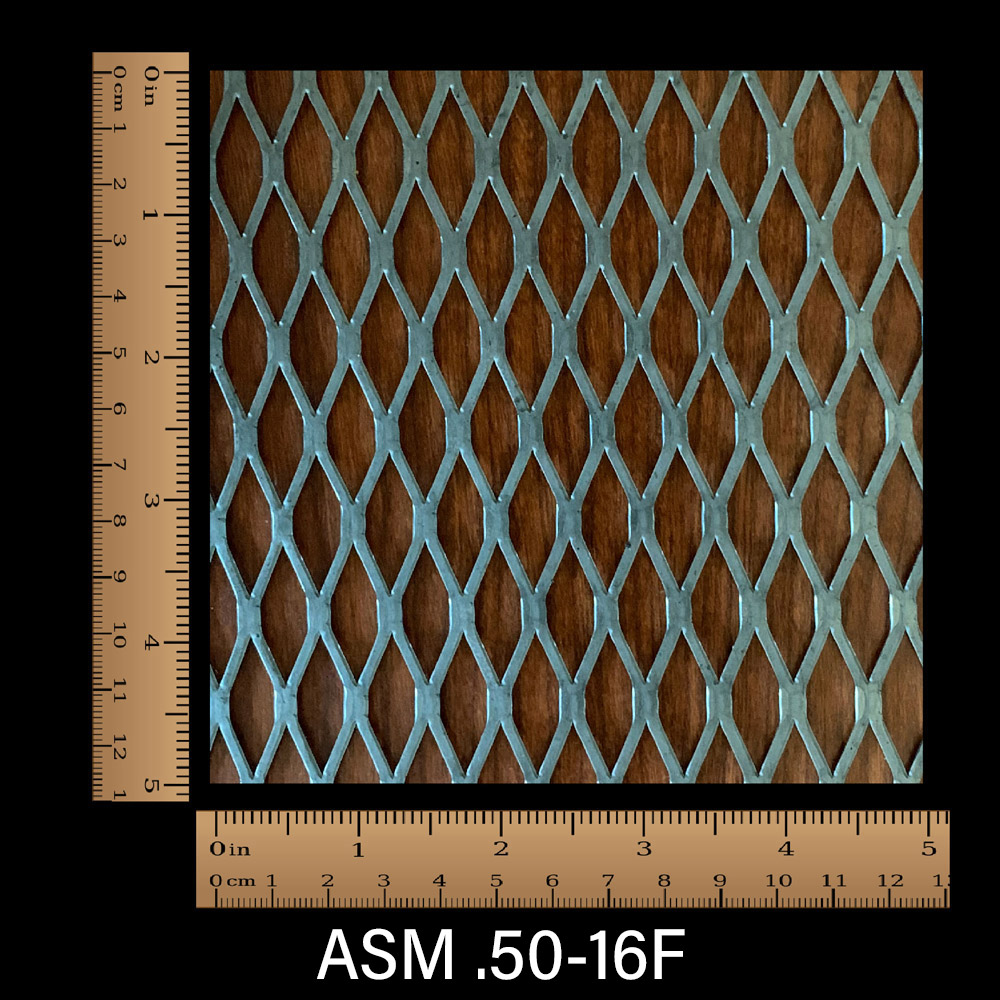

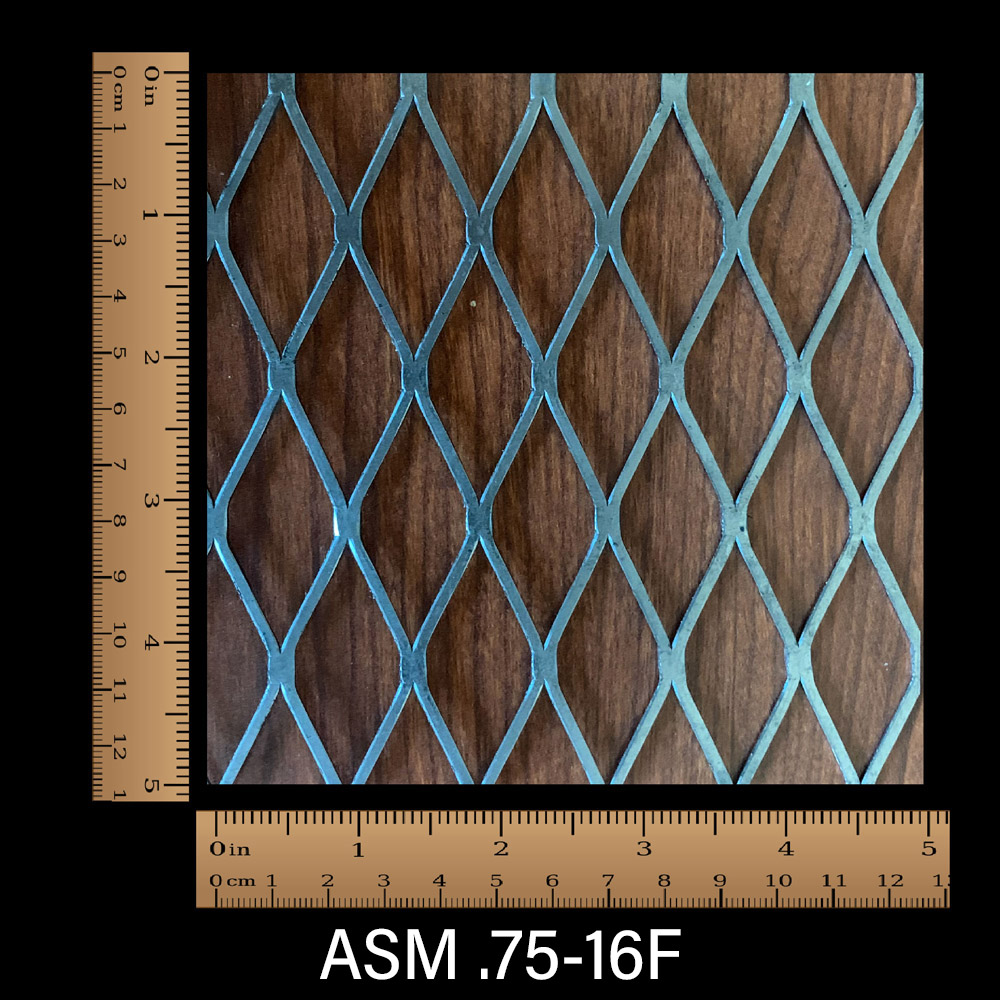

Security Mesh™ Selection

- AMICO offers Minimum, Medium, Maximum and Heavy Modified Super Max Security Mesh™ panels. The style of Security Mesh™ can be determined by the overall level of security for the facility and other conditions such as response time by security or law enforcement.

| AMICO Security Mesh™ | Weight per sq. ft. | Overall Thickness | Percent Open Area |

|---|---|---|---|

| ASM .75-9F HM | 2.38 lbs. | .140" | 63% |

| ASM .75-9F | 1.57 lbs. | .108" | 64% |

| ASM .50-13F | 1.26 lbs. | .072" | 57% |

| ASM 1.5-9F | 1.05 lbs. | .108" | 76% |

| ASM .75-13F | .67 lbs. | .072" | 77% |

| ASM 1.5-13F | .51 lbs. | .072" | 83% |

| ASM .50-16F | .77 lbs. | .048" | 61% |

| ASM .75-16F | .47 lbs. | .048" | 76% |

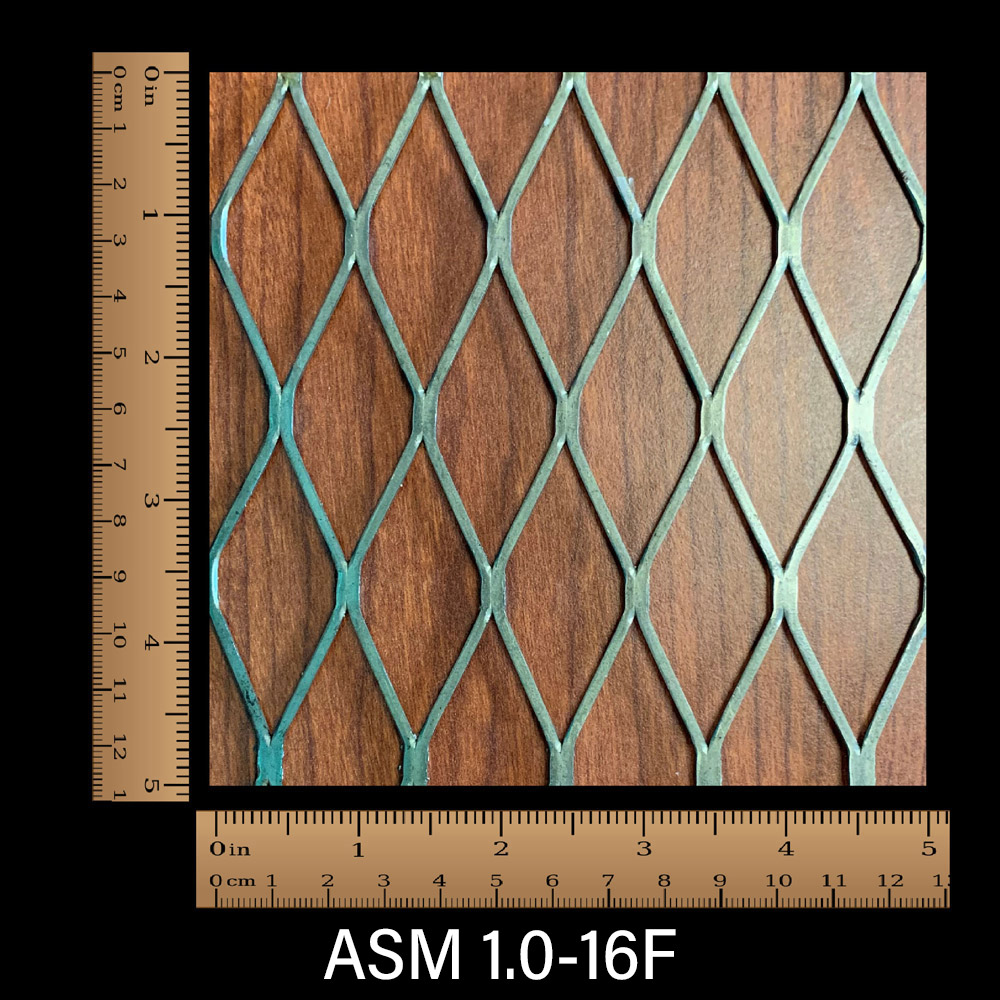

| ASM 1.0-16F | .38 lbs. | .048" | 80% |

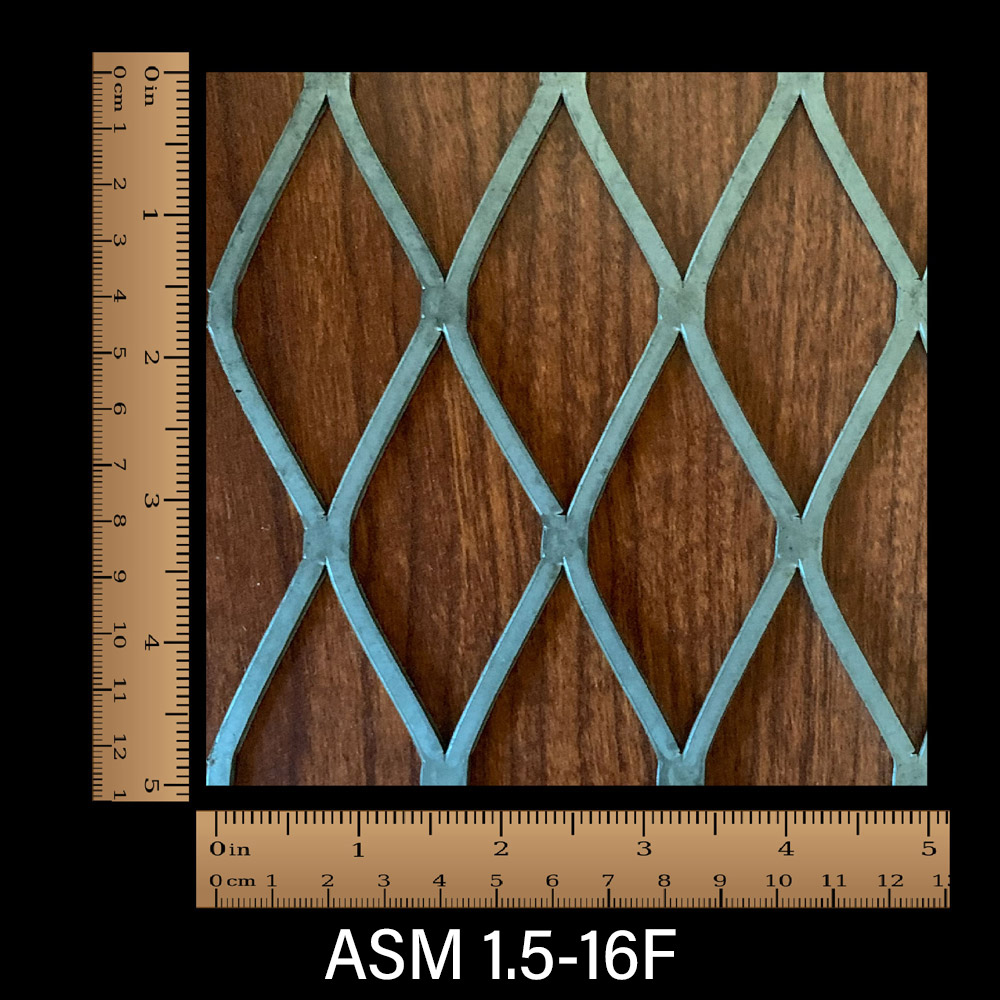

| ASM 1.5-16F | .35 lbs. | .048" | 82% |

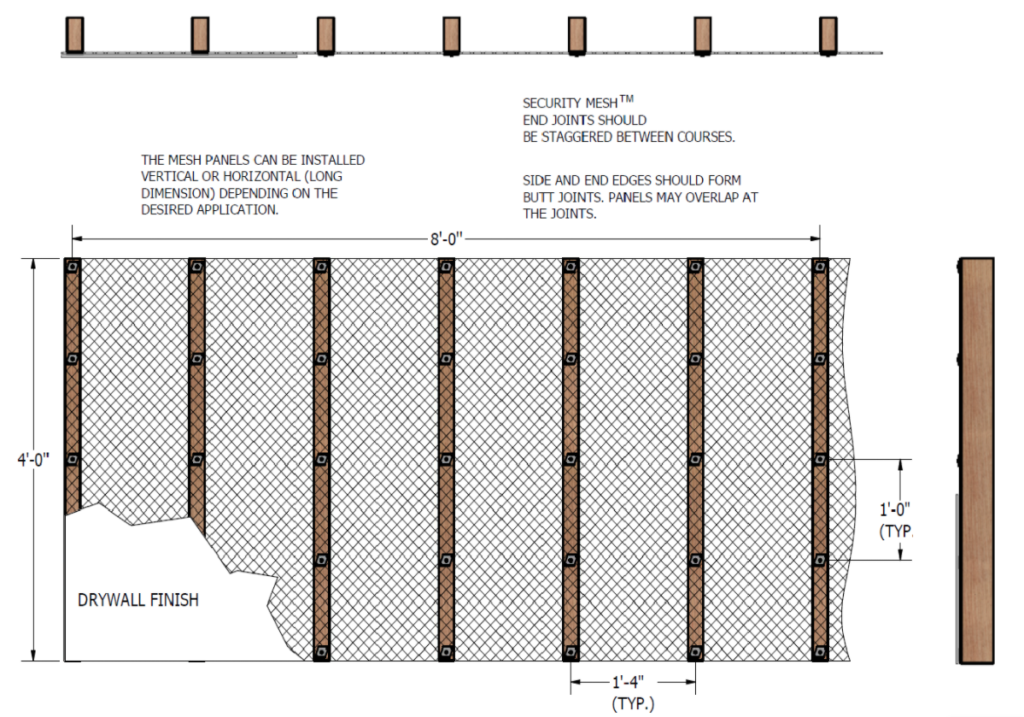

- Stud Spacing 16in (406.40mm) on center

- 24 Secura Clip® fasteners per 4′ x 8′ (1,219.20mm x 2,438.40mm) panel

- Secura Clip® fasteners spaced 12in (304.80mm ) vertically

- Stud Spacing 16in (406.40mm) on center

- 24 Secura Clip® fasteners per 4′ x 8′ (1,219.20mm x 2,438.40mm) panel

- Secura Clip® fasteners spaced 12in (304.80mm ) vertically

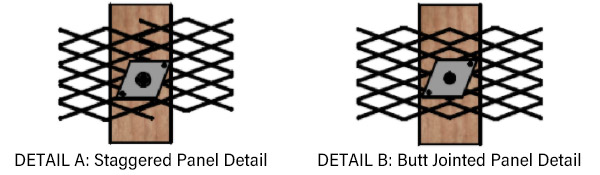

NOTE: Both Panel Joint Details are Acceptable Methods

- Framing members should be no less than 20GA

- Security Mesh™ panels may be installed with diamonds running in either direction

- It is preferred to have mesh joints either staggered as in detail “A” or butt joined as in detail “B”

- It is acceptable to overlap mesh joints with owners prior written approval

- Panels shall join on framing members

- If panels join in between framing members, in any direction, adjoining panels shall be tied with 18GA tie wire at the same frequency as clips or welding

- STEEL FRAMING APPLICATIONS Secura Clip® fasteners are fastened to steel framing members with fine thread self-tapping bugle head self-tapping screws with a #8 shank long enough to penetrate the steel framing member at least 3/8”

- WOOD FRAMING APPLICATIONS Secura Clip® fasteners are fastened to wood framing members with 1-5/8” fine thread #6 shank drywall screws

- On site, Security Mesh™ panels can be cut with a commercial nibbler, hand-held grinding with cutting wheel, circular saw with an abrasive or carbide tip blade, or cutting torch. When using grinding wheel and circular saw, anticipate sparks being emitted. It is not recommended to have Security Mesh™ panels sheared to size since each sheet will have numerous very sharp open diamonds creating transportation and jobsite hazards.

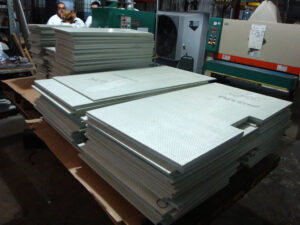

Ballistic Security Mesh™

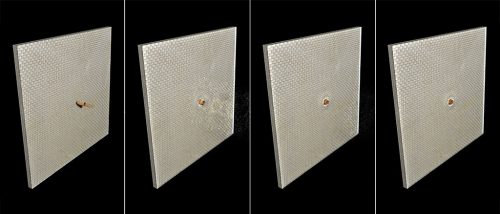

AMICO Ballistic Security Mesh™ Panels for ballistic protection behind drywalls are being manufactured by a world leading manufacturer of bullet resistant fiberglass. The composite laminate consists of fiberglass reinforced thermoset resin designed to defeat a projectile through a process of energy absorption through controlled delamination and energy dissipation.

The fiberglass reinforcement transfers the energy of the bullet across the width of the panel. In addition, the resin is designed to separate into individual plies through a process of controlled delamination to eventually absorb all the energy and stop the bullet within the laminate. Once the plies have begun to delaminate, additional shots become progressively easier to defeat because the energy is more readily absorbed by the laminate.

In contrast to metal barriers, the fiberglass laminate is designed to prevent ricochet of the projectile as well as spalling on the non-threat side of the bullet resistant panel.

Bullet resistant fiberglass panels are used to protect the employees, buildings, and other critical assets for many types of commercial and industrial organizations including: electric utilities, military and government facilities, law enforcement locations, and more.

Through our custom design for bullet-resistant panels, we’ve developed the highest quality and reliable product for defensive architecture.

Unique Benefits of Ballistic Security Mesh™

- Lighter Weight Than Steel

- Easy To Install With Standard Tools

- Effective Delay Against Forced Entry

- Low Wicking – No Build-Up Of Mold

- Non-Toxic Materials

- 1-Hour Fire Rating (ASTM E119-00)

- Available In Sizes Up To 5’ x 10’

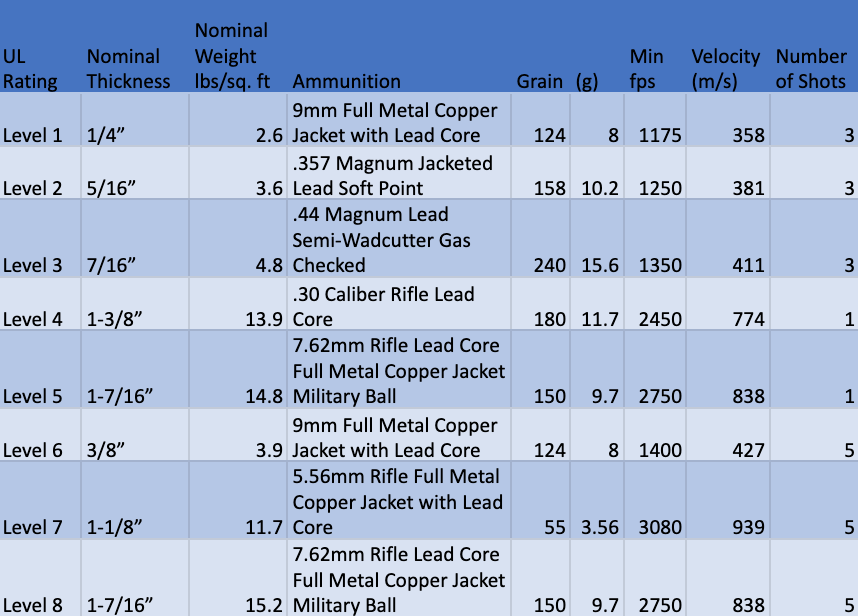

- Available In The Full Range Of UL 752

- 4′ x 8′ Size Level 1-3 Stocked for Quicker Lead times

High-quality materials, skilled craftsmanship and the best manufacturing processes are utilized in the fabrication of each and every AMIGUARD® Ballistic Panel. Continuous product testing ensures that our panels meet the highest criteria of ballistic resistive integrity.

AMICO Security’s bullet-resistant panels are manufactured by combining woven-roving fiberglass with resin, precision-assembled and cured in a press with heat and pressure while maintaining quality and consistency. With our unique capabilities including hydraulic presses, water jet cutting, industrial sanders and testing facilities, AMICO Ballistic Security Mesh™ Panels are offered in a variety of standard size sheets ranging from 3’, 4’ & 5’ widths by 8’, 9’ & 10’ lengths of any combination. We also offer custom cutting to fit your unique design with the ability to cut to any 2-dimensional size, pre-drill holes, bevel cut, etc. Our intensive Quality Assurance Program in conjunction with our ISO 9001:2015 registration will ensure every panel we manufacture meets and/or exceeds our customers’ requirements.

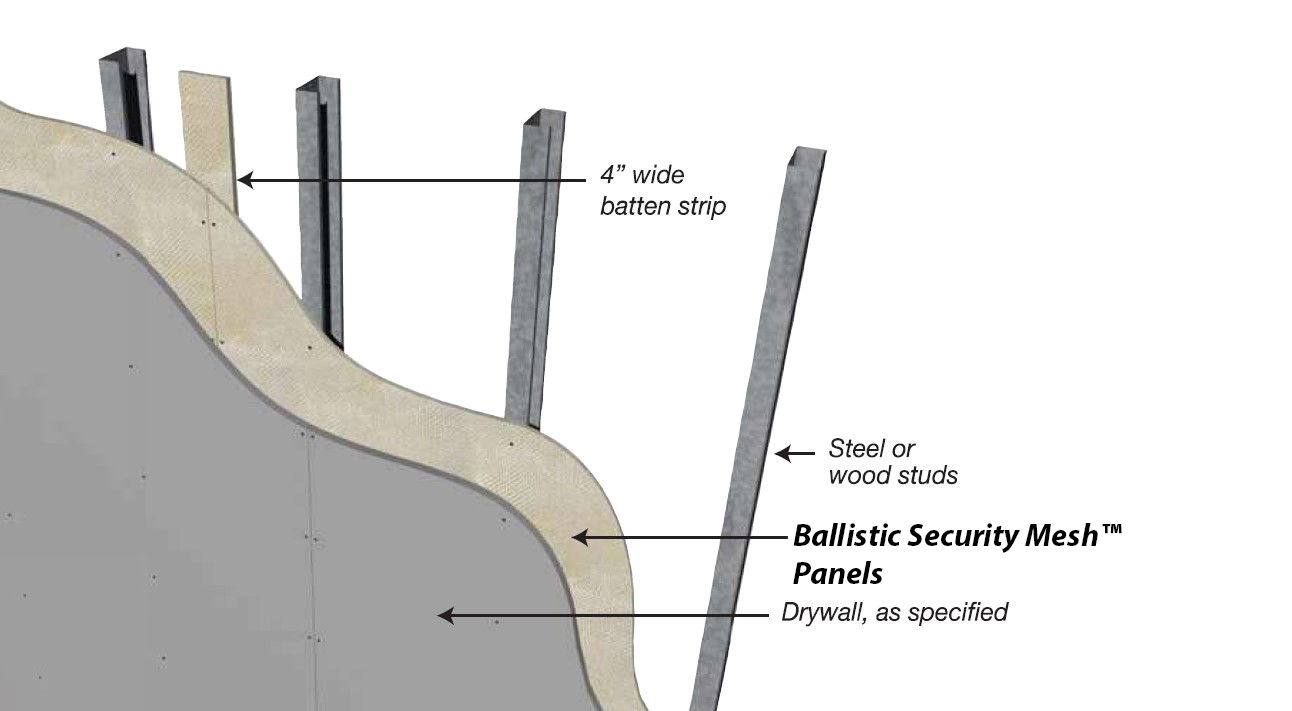

Ballistic Security Mesh™ Panels Installation

AMICO Ballistic Security Mesh™ panels may be attached using self-tapping drywall screws. When attaching a panel to a stud wall on which drywall will be the exteriorsurface, simply use enough screws to hold the panel to the studs, then come back with a complete screw pattern to the studs when hanging the drywall on top. If a different applique is to be used over the ballistic panels and a flush surface is required, a counter-sink hole may be used before adding the screws.

In the field, Ballistic Security Mesh™ panels can be cut with a diamond-grit blade. TSD 180D, manufactured by Tenryu, a quality 7” circular blade available through AMICO Security. For electrical boxes and other small openings, a diamond grit blade (available through most builder’s supply in the ceramic tile section) on a reciprocating saw should be sufficient.

Commercial Property

A wide range of commercial facilities face ballistic threat, most often those dealing with sensitive materials or quant ities of cash. AMICO Ballistic Security Mesh™ panels are highly effective within counter and wall systems to provide personnel protection from ballistic attack and rifle attack.

- Banks and Credit Unions

- Convenience Stores

- Check Cashing Facilities

- Data Centers

Government Property

Facilities at all levels of government need to consider protection against ballistic attack. From Federal courthouses to county jails, military facilities and local school board chambers, AMICO Ballistic Security Mesh™ panels provide affordable security within walls, lecterns and desks.

- Courthouses / Court Rooms

- Embassies & Consulates

- Public Safety Facilities

- Educational Facilities

- Military Facilities

Residential Security

Manufactured to meet the stringent ASTM “Forced Entry Protection” standards, AMICO Ballistic Security Mesh™ panelsare an ideal choice for residential Safe Rooms defending against room entry from bullets, as well as sledgehammers, cutting tools and even a propane torch!

Test results of AMICO Ballistic Security Mesh™ Level 3 panels by the Wind Engineering Research Center at Texas Tech University indicated that AMICO Ballistic Security Mesh™ can withstand a 15 lb. 2×4 wood board cannon-fired at a force consistent with a “large missile” typical of an EF-5 tornado, for effective storm shelter construction.