Security Mesh™ was developed and introduced by AMICO in the late 1980s as a penetration barrier for use behind drywall finishes. In 2002, AMICO patented the Secura Clip™, making a system that designers and security professionals can count on to provide the highest levels of physical security.

AMICO SECURITY MESH™

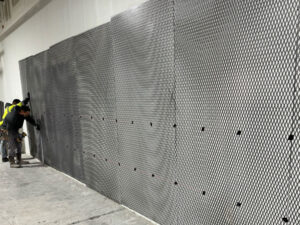

AMICO Security Mesh has been installed for decades in government, commercial, and retail buildings all over the world.

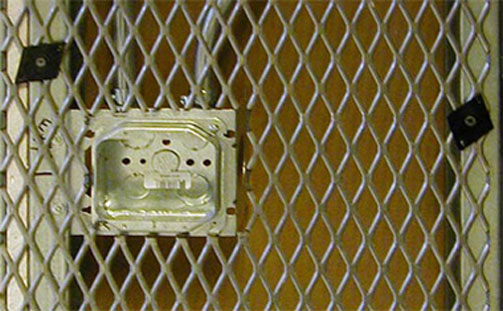

AMICO’s patented Secura Clips™ complete the system. Secura Clip™ fasteners have a recessed center hole allowing the Tek screw to seat at the surface of the mesh and not create humps and bumps alerting intruders to the penetration barrier.

Secura Clip™ fasteners provide over 68% more holding strength than standard screws alone.

Gypsum finish is installed directly over Security Mesh™. No need for other materials for added intrusion protection.

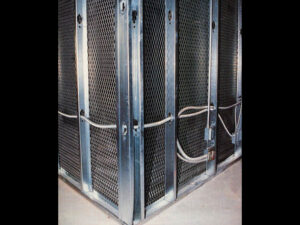

AMICO has supplied numerous projects requiring mesh to be attached to both sides of the framing members.

Before

After

APPLICATIONS

COMMERCIAL PROPERTY

Commercial malls are a great application for AMICO Security Mesh™. While storefronts are often secured by shutters, the walls on the side and back of the stores are often simple drywalls. Break-ins frequently occur through those walls since they often border hallways or less secure stores.

- Banks and Credit Unions

- Cellphone Stores

- Jewelry Stores

- Electronics Stores

- Data Centers & High Value Storage Facilities

CELL PHONE & JEWELRY STORES

Standalone cell phone and jewelry stores in strip malls are also targets for break-ins. Similar to mall stores the front of the stores are usually very secure, while the back and side walls could benefit from the addition of AMICO Security Mesh™.

DATA CENTERS

AMICO Security Mesh™ enhances security to Data Centers and high value storage facilities by significantly increasing the breach times compared to traditional walls. Since attackers are not aware of the presence of Security Mesh™, they often give up upon encountering Security Mesh™. In data centers, Security Mesh™ allows the air flow required while providing a barrier that is difficult to breach anywhere in the wall or ceiling systems.

Also the additional time required to breach walls fitted with Security Mesh™ increases the time for law enforcement to respond.

CANNABIS INDUSTRY

The cannabis and recreational drug industry faces many security challenges. Security Mesh™ is ideal to increase the security of walls and to increase security of storage rooms within those facilities.

COMPONENTS

ASM .75-9F HM Super Max Security

ASM .75-9F Maximum Security

ASM .50-13F Maximum Security

ASM 1.5-9F Medium Security

ASM .75-13F Medium Security

ASM 1.0-16F Minimum Security

AMICO Security Mesh | Weight per sq. ft. | Overall Thickness | Percent Open Area |

ASM .75-9F HM | 2.38 lbs. | .140" | 63% |

ASM .75-9F | 1.57 lbs. | .108" | 64% |

ASM .50-13F | 1.26 lbs. | .072" | 57% |

ASM 1.5-9F | 1.05 lbs. | .108" | 76% |

ASM .75-13F | .67 lbs. | .072" | 77% |

ASM 1.5-13F | .51 lbs. | .072" | 83% |

ASM .50-16F | .77 lbs. | .048" | 61% |

ASM .75-16F | .47 lbs. | .048" | 76% |

ASM 1.0-16F | .38 lbs. | .048" | 80% |

ASM 1.5-16F | .35 lbs. | .048" | 82% |

MESH SELECTION

AMICO offers Minimum, Medium, Maximum and Heavy Modified Super Max Security mesh panels. The style of mesh can be determined by the overall level of security for the facility and other conditions such as response time by security or law enforcement.

MESH FINISH

Security Mesh®is supplied in a Mill Finish (HR P&O – Hot Rolled Pickled & Oiled) as standard. For special applications such as installation adjacent to shower or kitchen areas, Hot dip galvanized is available upon request.

FRAMING

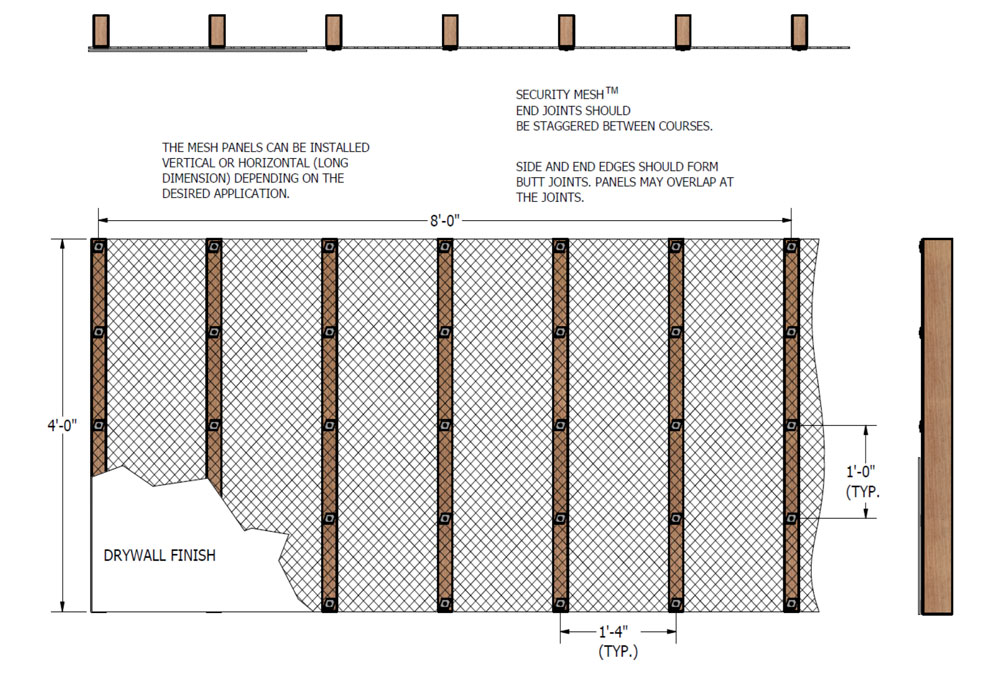

Generally, vertical framing members are set 16-inches on center. Horizontal ceiling members are set 16 to 24-inches on center. As the requirements for higher levels of security arise the spacing of vertical framing can be reduced to 12-inches on center. 12-inch stud spacing is frequently specified with the ASM .75-9F Heavy Modified.

SECURA CLIP™ FASTENERS

For best performance AMICO Secura Clip™ fasteners need to be used. Install clips to metal framing using bugle head self-tapping screws penetrating the framing member a minimum of 3/8-inch. With wood framing use 1-5/8-inch drywall screws allowing the fastener to penetrate framing a minimum of 1-1/2-inches.

Standard spacing is 12-inches vertically per framing member for both vertical and horizontal surfaces.

PROJECT EXAMPLES

Click on image gallery to scroll through photos

INSTALLATION

AMICO SECURA CLIP™ SPACING GUIDELINES

- Stud Spacing 16in (406.40mm) on center

- 24 Secura Clip™ fasteners per 4’ x 8’ (1,219.20mm x 2,438.40mm) panel

- Secura Clip™ fasteners spaced 12in (304.80mm) vertically

One box contains 300 Secura Clip™ fasteners and weighs 3.5 lbs. per box

- Steel Stud Installations – Use self-tapping bugle head screws

- Wood Stud Installations – Use standard drywall screws

- Screws not included with clips

AMICO SECURITY MESH™ INSTALLATION NOTES

- Framing members should be no less than 20GA

- Security Mesh™ panels may be installed with diamonds running in either direction

- It is preferred to have mesh joints either staggered as in detail “A” or butt joined as in detail “B”

- It is acceptable to overlap mesh joints with owners prior written approval

- Panels shall join on framing members

- If panels join in between framing members, in any direction, adjoining panels shall be tied with 18GA tie wire at the same frequency as clips or welding

- STEEL FRAMING APPLICATIONS Secura Clip™ fasteners are fastened to steel framing members with fine thread self-tapping bugle head self-tapping screws with a #8 shank long enough to penetrate the steel framing member at least 3/8”

- WOOD FRAMING APPLICATIONS Secura Clip™ fasteners are fastened to wood framing members with 1-5/8” fine thread #6 shank drywall screws

CUTTING OF AMICO SECURITY MESH™ PANELS

On site, panels can be cut with a commercial nibbler, hand-held grinding with cutting wheel, circular saw with an abrasive or carbide tip blade, or cutting torch. When using grinding wheel and circular saw, anticipate sparks being emitted. It is not recommended to have panels sheared to size since each sheet will have numerous very sharp open diamonds creating transportation and job-site hazards.

Caution

Cutting of Security Mesh™ panels may be required for installation. When these steel panels are cut, the resulting open diamond is very sharp. Safety precautions are to be taken. Gloves and eye protection should be worn when cutting panels.

UNDERWRITERS LABORATORIES FIRE RATING

Underwriters Laboratories Fire Rated Assembles will not be jeopardized by using AMICO’s Security Mesh™ in the fire rated assembly (per U/L subject File #1857).

Additional Resources

Documents

Tech Center

Looking for additional technical drawings? Visit our Tech Center.

Installation