Each AMIGUARD® 6000 Security Mesh and AMIGUARD® 7000 High Security Mesh panel goes through a process of slitting and stretching metal sheet to form the desired style. The Security Panel has strands and intersecting strands called bonds forming a sharp angle to the original plane of the solid sheet. This process creates the unique pattern and allows a single sheet of metal to be processed into several sheets of Security Mesh Panels.

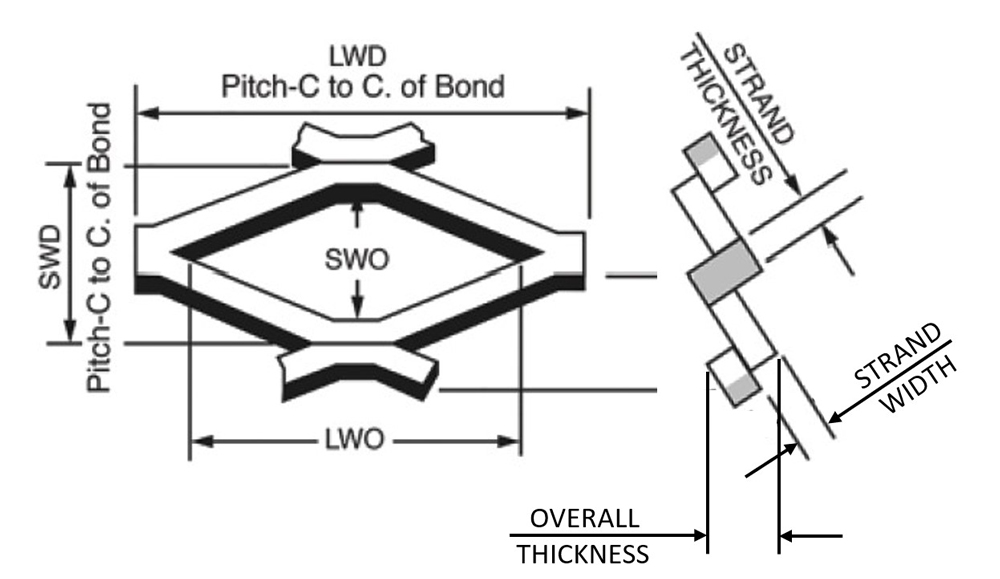

DEFINITIONS

- Bond = the solid intersection of two strands.

- Diamonds = open area of metal after expanding.

- Percent of Open Area = The relation of solid metal to open diamond area.

- Pitch = The measurement from a point of a diamond to the same point on an adjacent diamond.

- LWD = nominal dimension, Long Way of the Diamond, center of bond to center of bond.

- SWD = nominal dimension, Short Way of the Diamond , center of bond to center of bond.

- LWO = Long Way of the Opening.

- SWO = Short Way of the Opening.

- Strand thickness = thickness of the base metal.

- Strand width = forward motion os sheet during production.

- Overall Thickness = thickness of raised expanded metal.

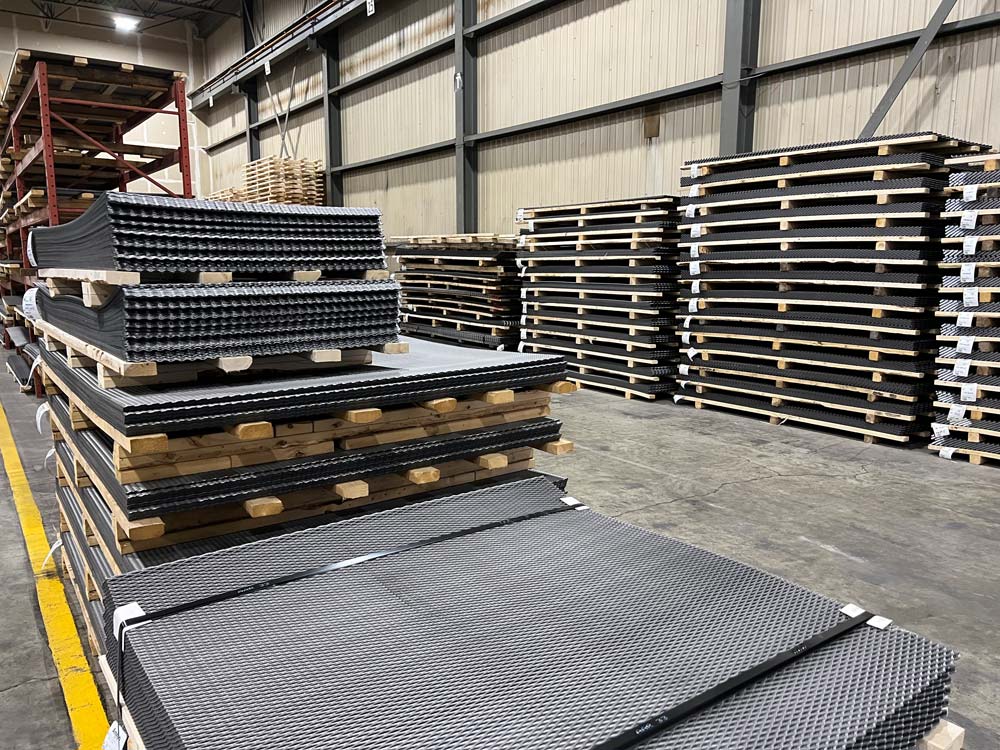

AMICO is the largest expanded metal manufacturer in North America, and AMICO Security offers a wide range of AMIGUARD® 6000 Security Mesh and AMIGUARD® 7000 High Security Meshes. Meshes differentiate by weight and the size of the diamond openings. All meshes are available in Hot Dipped Galvanized or Black Powder coating over zinc primer/zinc e-coating.

| AMIGUARD® Mesh Style | Short Way of Diamond | Long Way of Diamond | Percent Open Area | Strand Thickness (in) | Strand Width (in) | Weight per sq. ft. galv. |

|---|---|---|---|---|---|---|

| 6030 | 1.85 | 4.00 | 84% | .134 | .149 | .990 |

| 6050 | 1.33 | 3.00 | 78% | .134 | .144 | 1.310 |

| 6100 | 0.500 | 1.20 | 62% | .090 | .096 | 1.634 |

| 6200 | 0.923 | 2.10 | 64% | .108 | .165 | 1.749 |

| 6300 | 0.923 | 2.00 | 67% | .134 | .150 | 1.964 |

| 6800 | 1.33 | 3.00 | 69% | .198 | .203 | 2.651 |

| 7100 | .500 | 1.20 | 25% | .090 | .188 | 3.10 |

| 7300 | 1.28 | 3.00 | 6% | .075 | .600 | 3.18 |

| 7500 | .925 | 3.00 | 14% | .090 | .400 | 3.50 |

| 7700 | 1.00 | 2.40 | 52% | .179 | .240 | 3.76 |

| 7800 | 1.00 | 2.25 | 50% | .179 | .250 | 3.92 |

Tolerances: Short Way of Diamind (SWD) & Long Way of Diamond (LWD) 0 + 0.25″ per 12″ of width.

TYPES OF EXPANDED METAL

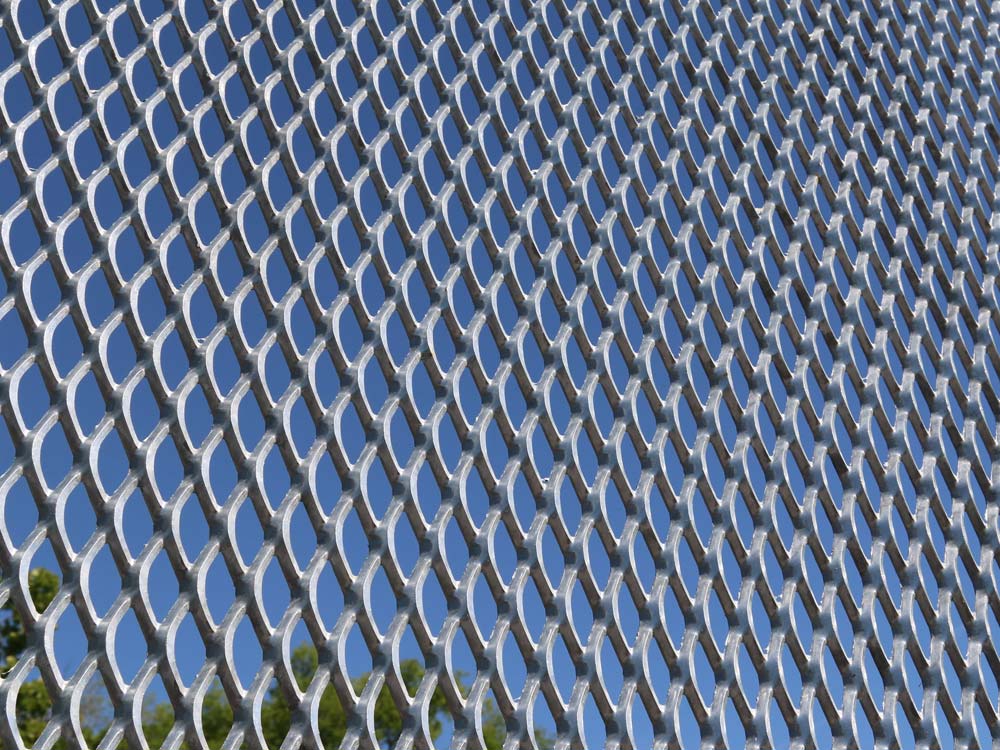

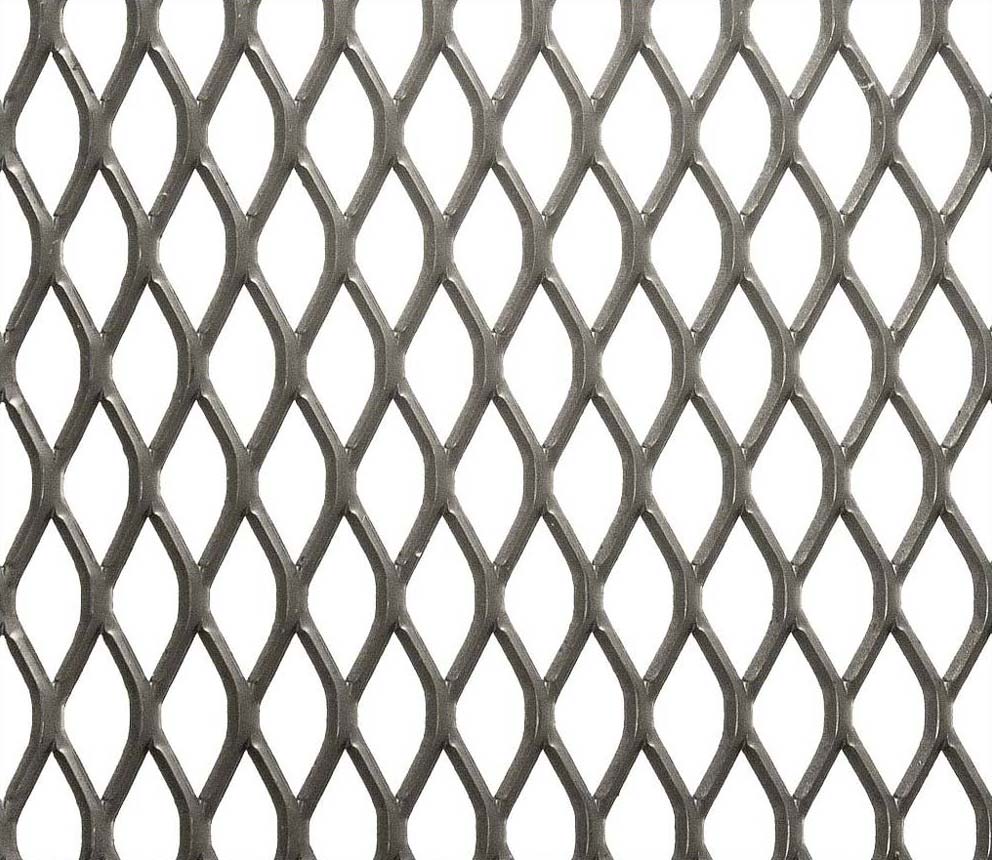

Standard Expanded Metal

Standard expanded metal is extremely versatile and economical. It comes in a variety of gauge and opening sizes. It’s often used to provide a rigid, raised, slip-resistant surface. In standard expanded metal the strands and bonds are set at a uniform angle. This provides extra strength and rigidity whilst allowing maximum air circulation.

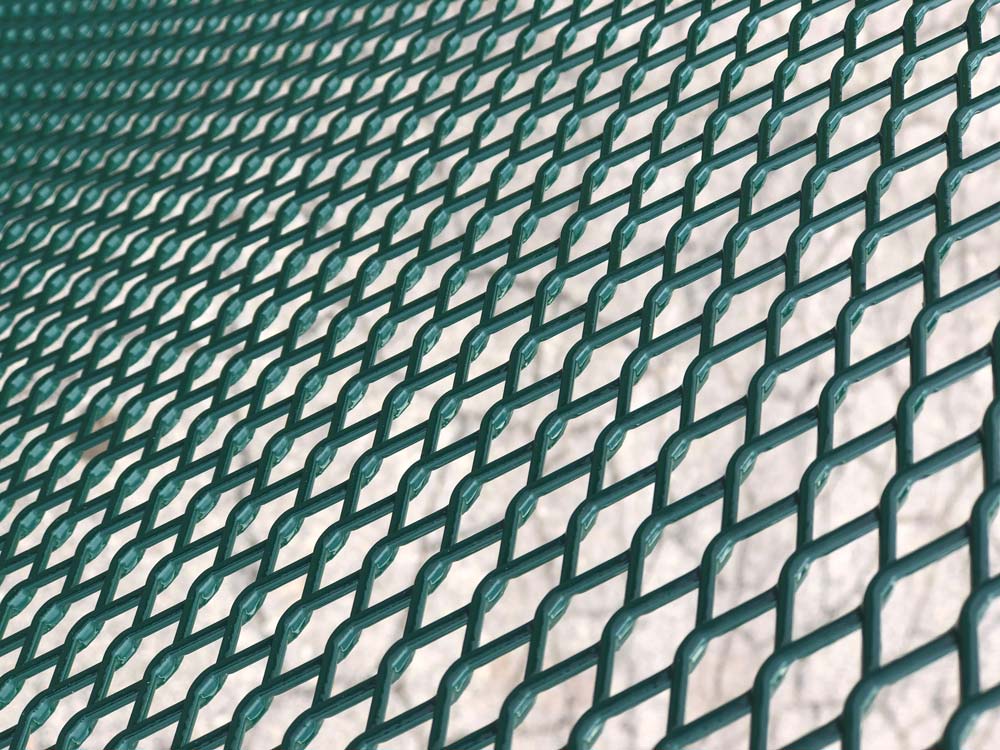

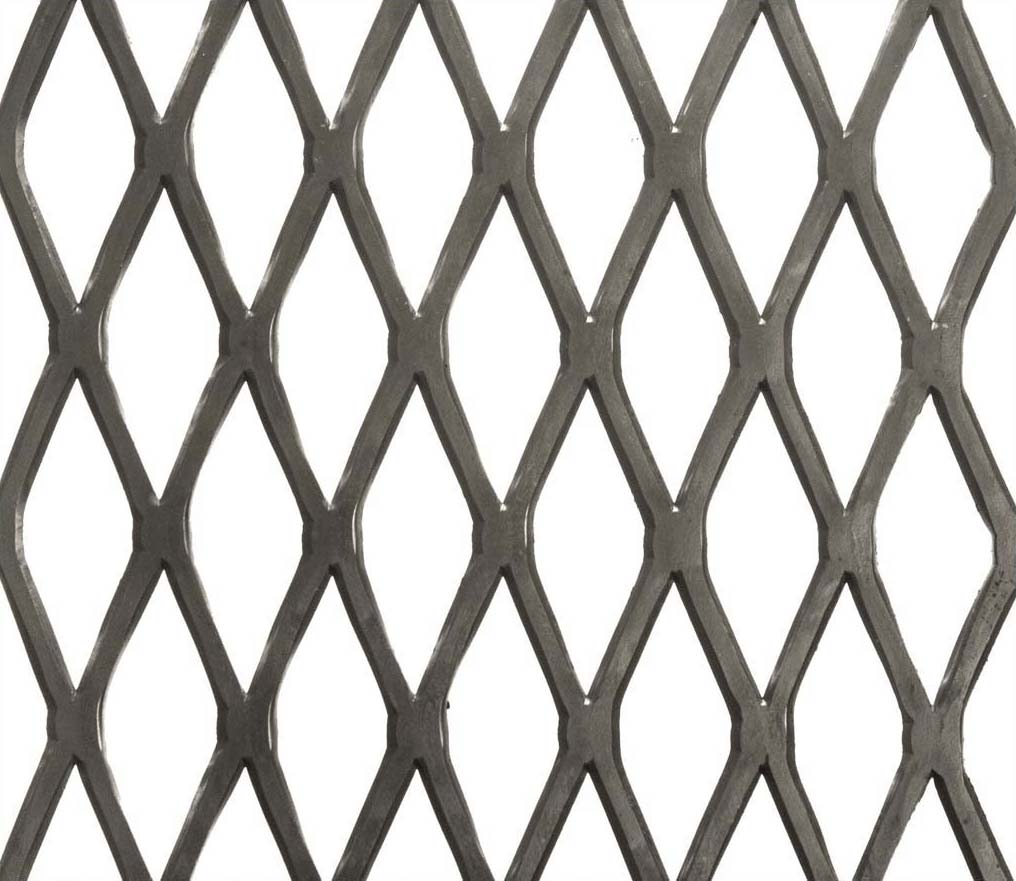

Flattened Expanded Metal

Flattened expanded metal is produced by cold rolling expanded metal to flatten it. It is chosen when a smooth surface is required. The flattening process generally elongates the length of the sheet by 5%

Hexagonal Expanded Metal

Hexagonal expanded metal has hexagonal openings instead of the usual diamond ones. The hexagonal shape gives the metal extra strength while allowing the passage of air, light, heat, sound and liquid. Hexagonal openings are preferred over diamond openings when the metal is heavily expanded.

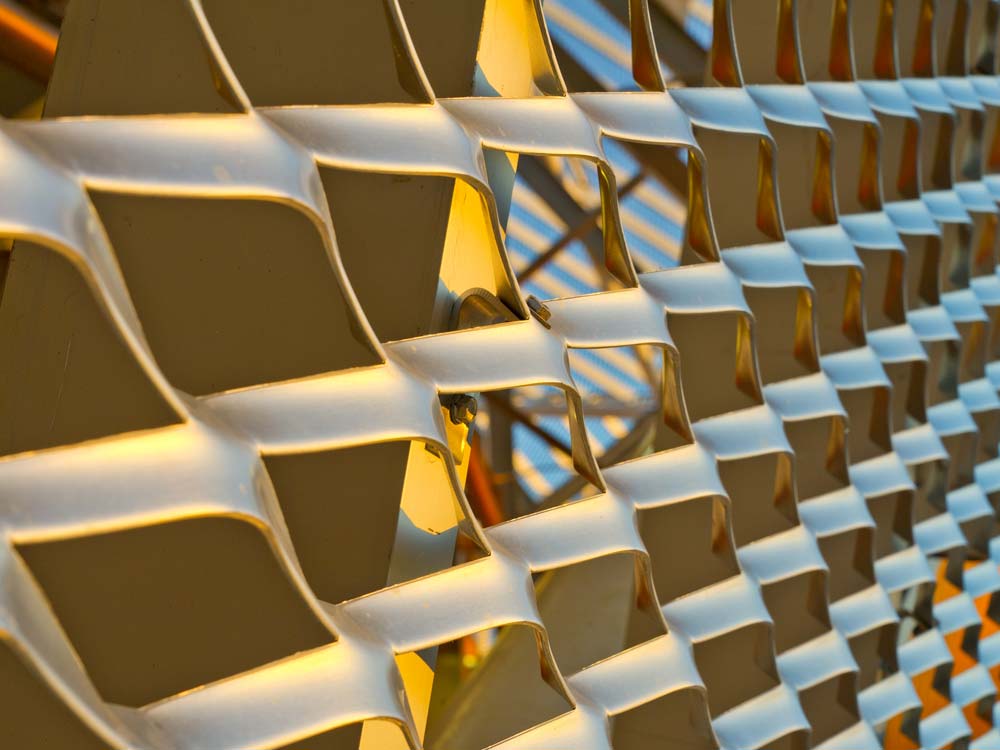

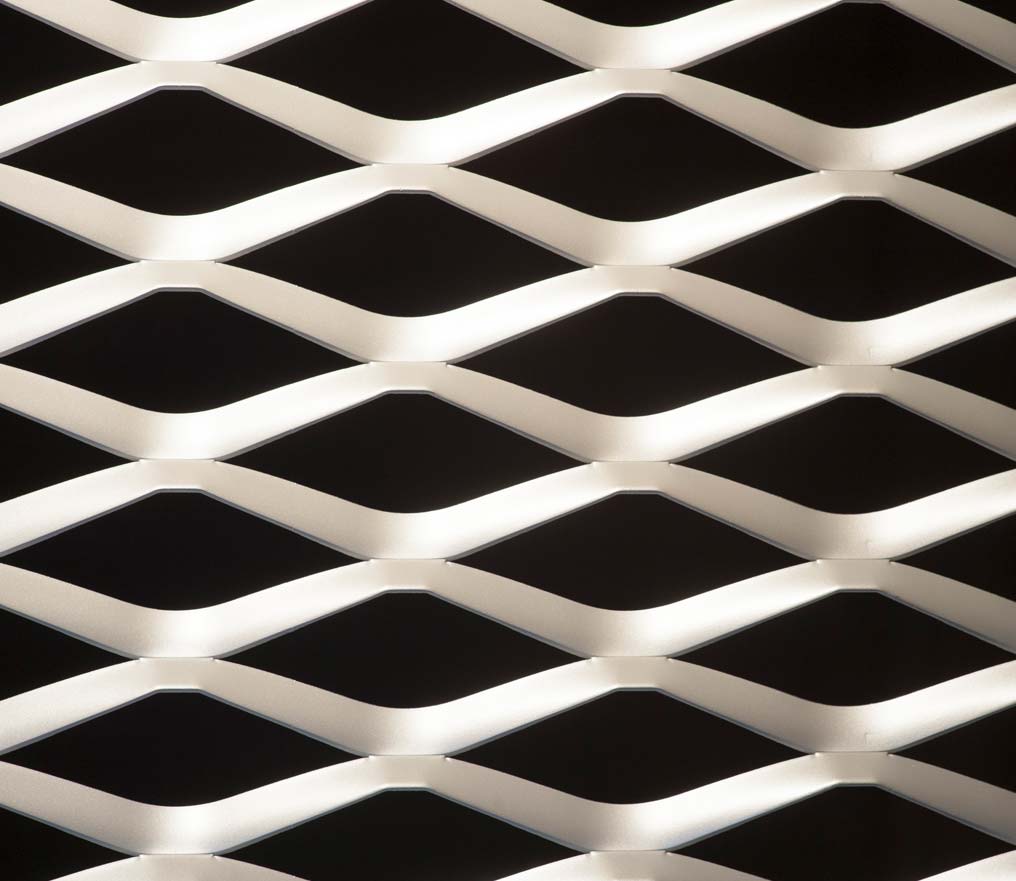

Architectural Expanded Metal

Architectural expanded metal features the diamond pattern with added architectural features. The result is a design which combines good aesthetics, increased security and privacy, and improved ventilation. It’s suitable for functional and decorative purposes, or a combination of the two.

Micro Expanded Metal

Micro expanded metal features small openings in light gauge metal. The openings can be standard, flattened, hexagonal and square. This type of expanded metal is often used in filters.

Made by AMICO the largest expanded metal manufacturer in North America

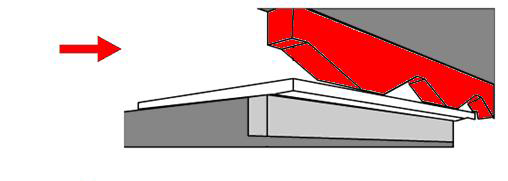

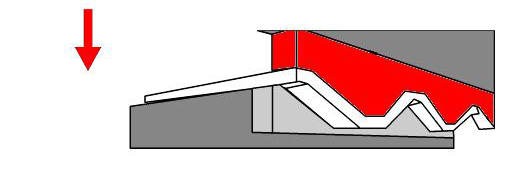

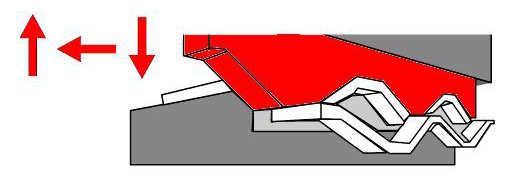

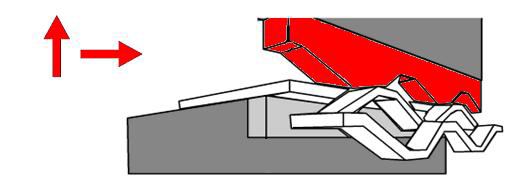

FOUR STEPS IN THE MANUFACTURING PROCESS

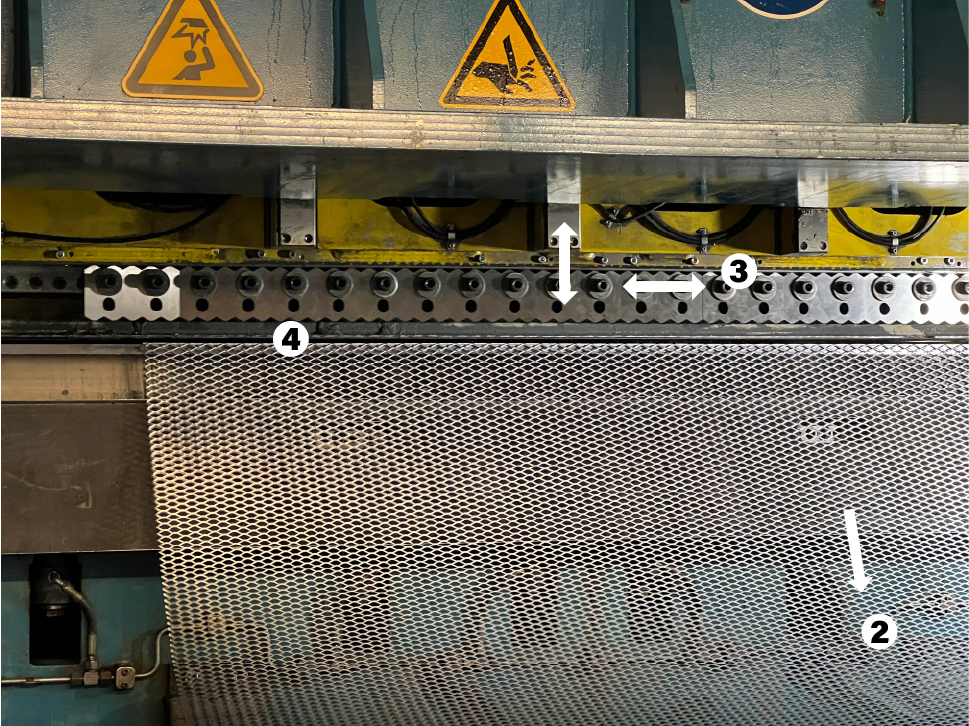

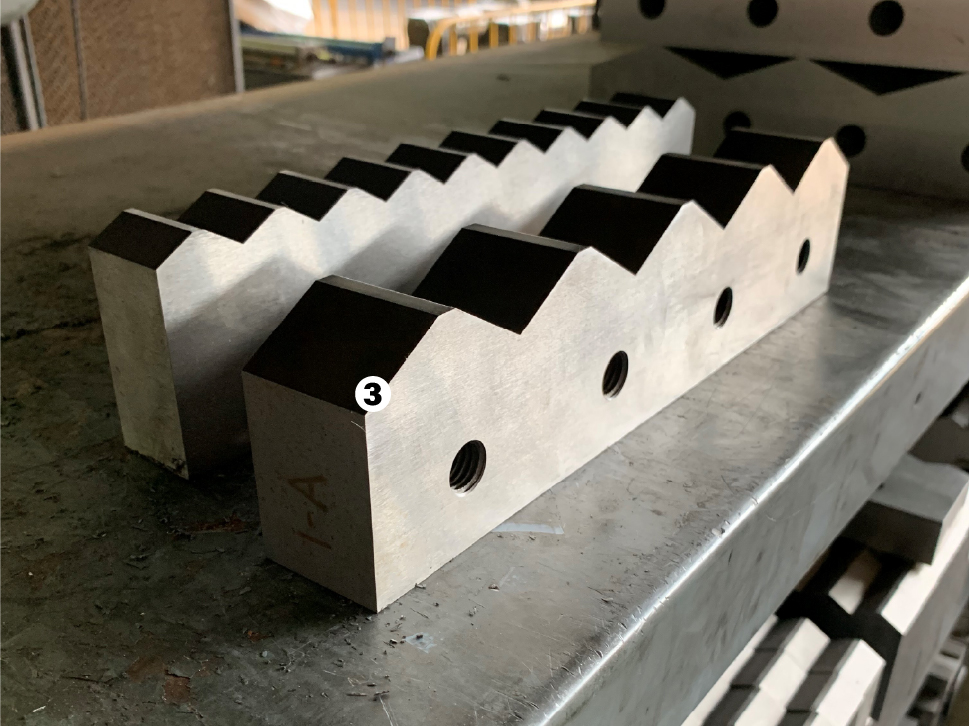

3

The upper blade ascends to its original starting and transverses shift one half of diamond to the side as the metal sheet advances another strand width passing the edge of the lower blade. The upper blade descends again to form another row of half diamonds to complete a full diamond pattern.

4

The upper blade ascends again to its original starting position, and the cycle continues until the sheet of expanded metal is complete.