AMICO SECURITY Offers Three Highly Corrosion Resistant Finishing Options:

- Hot-Dip Galvanizing

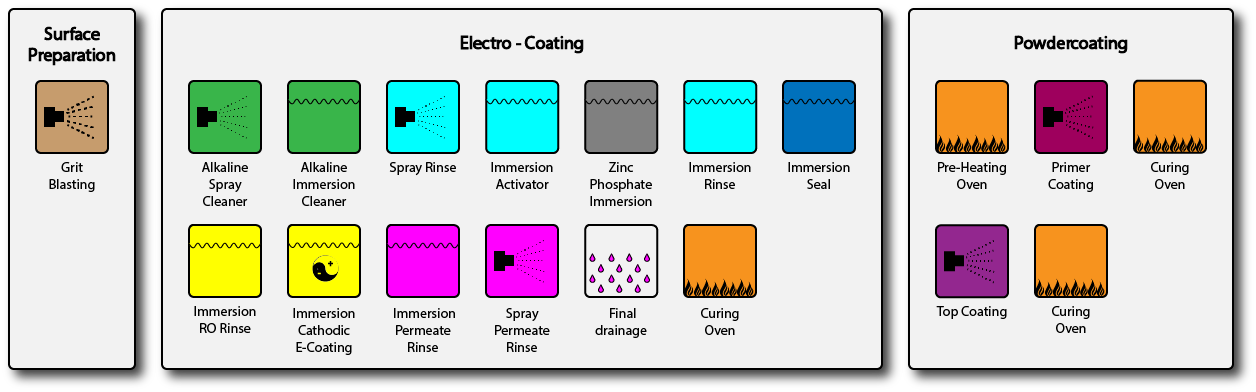

- AMICOAT™ Powder Coating over E-Coating or primer base

- AMICOAT™ Duplex Coating, Powder Coating over Hot-Dip Galvanizing

All of AMICO Security’s finishing processes involve a zinc layer for superior corrosion protection. While a traditional paint layer aims to prevent water from touching the steel, a zinc layer provides a superior cathodic protection replacing the steel anode with a zinc anode resulting in zinc oxide which forms a protective layer instead of rust.

- All components are Hot Dipped Galvanized

- Meets ASTM A123 standard

- 10 Year limited Warranty

HOT-DIP GALVANIZING

HOT DIP GALVANIZING PROJECT EXAMPLES

Click on image gallery to scroll through photos

AMICOAT™ POWDER COATING

AMICOAT™ POWDER COATING PROJECT EXAMPLES

Click on image gallery to scroll through photos

- Industry Leading AMICOAT™ Duplex Coating with Powder Coat Coverage over Hot-Dipped Galvanizing

- AMICOAT™ available in 16 standard colors

- ALL Colors of the RAL Color Chart are available upon request

- 10 Year Limited Warranty

AMICOAT™ DUPLEX COATING

Duplex Coating provides a more sophisticated manner of corrosion protection known as the synergistic effect. The hot-dip galvanized steel is powder coated providing two layers of protection. Used independently, both paint/powder coatings and galvanizing provide corrosion protection to steel; however, when utilized together, the two coatings work in synergy. The exterior layer of paint or powder coating slows down the rate at which the zinc is consumed, greatly extending the life of the galvanized steel. In return, once the exterior layer has been weathered down or damaged, the zinc beneath is still available to provide cathodic and barrier protection.

AMICOAT™ DUPLEX COATING PROJECT EXAMPLES

Click on image gallery to scroll through photos

Please note that standard AMICOAT™ colors shown in here are for reference only as they can deviate slightly from the actual colors depending on electronic screen or printing.

FINISHES

All of AMICO Security’s finishing processes involve a zinc layer for superior corrosion protection. While a traditional paint layer aims to prevent water from touching the steel, a zinc layer provides a superior cathodic protection replacing the steel anode with a zinc anode resulting in zinc oxide which forms a protective layer instead of rust.

Additional Resources

Documents

Tech Center

Looking for additional technical drawings? Visit our Tech Center.

Installation