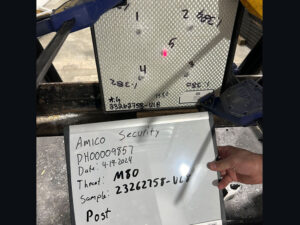

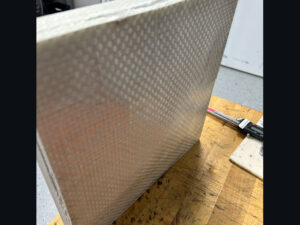

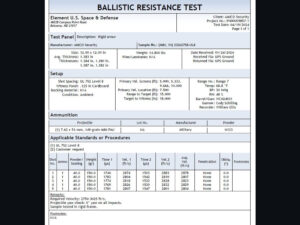

High-quality materials, skilled craftsmanship and the best manufacturing processes are utilized in the fabrication of each and every AMIGUARD® Ballistic Panel. Continuous product testing ensures that our panels meet the highest criteria of ballistic resistive integrity.

The first element of manufacturing quality bullet-resistant panels is using only reliable and long-lasting raw materials. One reason that the AMICO Security product line has

become the preferred bullet resistant fiberglass panel is our commitment to not use starch-oil fiberglass, which is organic and tends to break down in time.

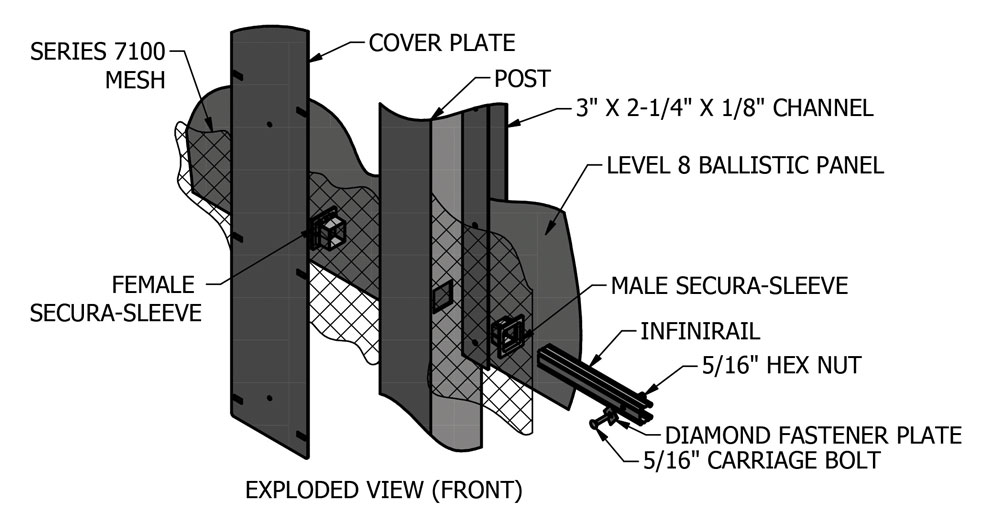

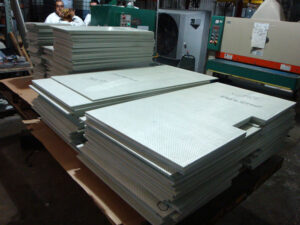

AMICO Security’s bullet-resistant panels are manufactured by combining woven-roving fiberglass with resin, precision-assembled and cured in a press with heat and pressure while maintaining quality and consistency. With our unique capabilities including hydraulic presses, water jet cutting, industrial sanders and testing facilities,

AMIGUARD® Ballistic Panels are offered in a variety of standard size sheets ranging from 3’, 4’ & 5’ widths by 8’, 9’ & 10’ lengths of any combination.

We also offer custom cutting to fit your unique design with the ability to cut to any 2-dimensional size, pre-drill holes, bevel cut, etc. Our intensive Quality Assurance Program in conjunction with our ISO 9001:2015 registration will ensure every panel we manufacture meets and/or exceeds our customers’ requirements.